Apple’s Reliance on China Grows Perilous With Chaos in iPhone City

By Bloomberg News

24 November 2022

BEIJING – Mr Xiao Han was just wrapping up the week-long quarantine that marked the beginning of his latest stint working at the sprawling manufacturing complex in Zhengzhou, China, known as “iPhone city” when violence erupted there in late November.

A large part of the 200,000-person workforce had already spent weeks living in forced isolation in trash-filled dormitories, subsisting on meagre rations because management wanted to keep churning out Apple devices while squelching a Covid-19 outbreak.

On Nov 23, hundreds of workers, angry to learn they might not get the wages they were promised unless they kept at their jobs throughout the Spring Festival and into mid-March, pushed past the security staff guarding their living quarters, setting off a physical confrontation with riot police.

“It was total chaos,” said Mr Xiao, who added that some of his co-workers were injured in the clash. “I’d never expected things could go this bad.”

Mr Xiao, 30, describes a situation that grew intolerable even before the violence. He helped make iPhones on Chinese assembly lines for more than a decade.

In October, he was part of a wave of workers who abandoned iPhone city, the world’s largest iPhone assembly complex, in response to unsanitary and deteriorating conditions.

Then, too, workers clashed with guards over food shortages and living conditions. Workers gave up coveted jobs and, in one case, fled on foot and walked for 40km to get home.

But Mr Xiao returned in mid-November, lured by special bonuses intended to convince exhausted workers that things were improving.

The violence that peaked on Nov 23 showed how inadequate that effort has been, while also exposing the increasing futility of China’s Covid-19 strategy.

Throughout the pandemic, the Communist Party of China has shown a willingness to go to extremes in its efforts to combat Covid-19.

It pushed companies such as Foxconn Technology Group and Tesla to cut off their facilities from the outside world, then continue operating them as “closed-loop systems”.

Taiwan’s Foxconn, Apple’s main manufacturing partner, operates iPhone city independently.

It has acknowledged that it has made mistakes in managing the employees, while blaming local officials for unpredictable policies that made meal delivery and maintenance almost impossible, according to a person familiar with the company who asked not to be named discussing private matters.

Foxconn’s troubles have drawn the most attention because of the company’s prominence and size. But its struggles suggest that others may be having even more trouble operating within the parameters of China’s policies.

“You see cases like Foxconn, and every company is now asking themselves, ‘Will that happen to me?’” said Ms Alicia Garcia Herrero, chief Asia-Pacific economist at Natixis. “Any company that depends on manufacturing has to consider alternatives. It will be costly, but it will be less costly than only relying on China and then China doesn’t open up.”

Ms Herrero said China’s economy could still take a year to 18 months to open up, and that it is vital that the government communicate clearly that it has a plan to recover.

In her view, China’s description of its plans so far have been muddled, running the risk that businesses will lose confidence and accelerate plans to develop manufacturing capabilities elsewhere.

“Beijing can’t take for granted that companies will keep their manufacturing in the country,” she said.

The Zhengzhou plant produces about 80 per cent of the latest iPhone 14 models, making its continued operation critical for Apple, which warned in November that shipments of its newest iPhones will be lower than expected going into the peak holiday season.

In a worst-case scenario, Morgan Stanley said, it is possible no more iPhones will be shipped from the site in 2022.

A spokesman for Apple said in a statement that the company has staff members at the Zhengzhou facility and was “reviewing the situation and working closely with Foxconn to ensure that their employees’ concerns are addressed”.

Mr Tim Cook, who championed the development of Apple’s China supply chain before he took over as chief executive from Mr Steve Jobs in 2011, is developing alternatives.

Assembly partners such as Foxconn are making more iPhone 14 models in India than any previous generation and are beginning to use India as an export base.

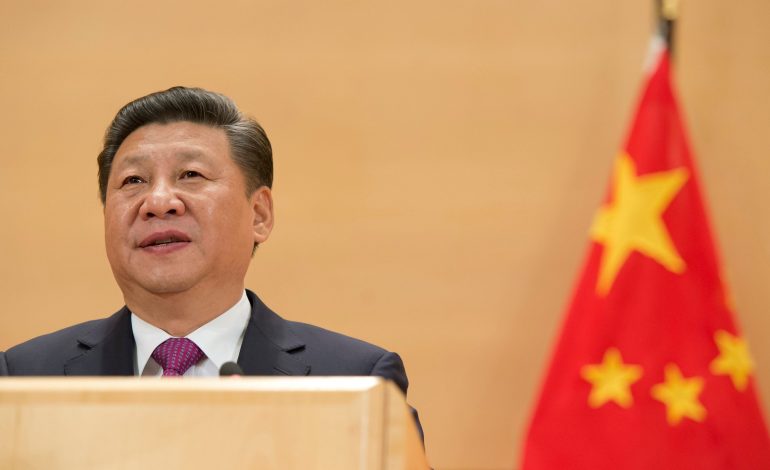

Foxconn is also expanding in Vietnam and Thailand. That is a sign of how Chinese President Xi Jinping’s Covid-19 policies are threatening China’s economic growth.

“It’s very telling that a company like Foxconn is already moving into other countries,” Ms Herrero said.

Long hours, bad food, isolation

Mr Xiao arrived at iPhone city in July, renting a room of a dozen square metres for 350 yuan (S$67) a month in a nearby town. The space was cheap because of its location – Mr Xiao had to walk more than 40 minutes to get to work. His job was simple: peeling protective plastic from display components that would be used on iPhones and other devices.

He has helped make every version, from the iPhone 5 to the iPhone 14, labouring 10 hours a day as production cranked up for a new model.

In early October, Mr Xiao heard rumours about Covid-19 infections at the campus. Soon after, Foxconn began asking workers to take designated commuting routes every day and stop any private gatherings, according to company announcements and workers inside the campus.

Yellow plastic barriers about 2m tall were set up along roads to create lanes for workers to commute between dorms and the factory, but the restrictions were often violated. Some of Mr Xiao’s colleagues climbed around the barriers to go into a town neighbouring the compound.

Foxconn did not say how widely Covid-19 spread into the compound, where groups of workers often share cramped living quarters. But on Oct 19, it closed its worker cafeterias on orders from the local authorities. That forced the company to quickly find another way to feed its workers.

This immediately led to problems.

Foxconn simply did not have the staff to prepare and deliver food boxes multiple times a day. So, meals were mostly given out as workers left the factory, with the intention that they would eat in their dorm rooms.

The cooked food often ran out, leaving many with only bread and boxed milk. Those who did not go into the factory – because they were sick or quarantined in their rooms – at times did not get anything, according to people who were at the complex at the time.

The quality of the food was poor, consisting of rice, shredded potato and fried bean sprouts.

Mr Xiao said the boxes he got smelled, and the dishes were commonly covered with a gooey substance. Many workers cooked instant noodles instead. They took to posting photos of the company meals on social media.

Mr Zeng Guang, a 21-year-old who polished metal cases at the factory, said he got stuck in his dorm room without food for a day after being categorised as having had close contact with someone who had Covid-19.

That night, he said, he grew so hungry that he went down to his building’s entrance to demand that the guards give him food. “They were so afraid,” he said, “as if I was wielding a knife”.

The daily Covid-19 testing also proved to be flawed. As many as 20 workers’ throat swabs were put into one tube to speed testing and lower costs. If the results came back positive, all the workers whose samples were in that one tube were put into isolation for further testing.

Those who worked on the same production line with someone who tested positive were also immediately removed from their duties and put into quarantine.

The number of potential patients surged by the hour, and the number of Covid-19-free workers who could go to the factory dwindled rapidly.

Mr Zeng was put into isolation three times in one week, he said, even though he ultimately never had Covid-19.

In some dormitories, trash piled up for weeks because no one was allowed to leave the building.

Covid-19-free workers nicknamed colleagues who got Covid-19 “sheep” because the word’s pronunciation is the same as “positive” in Mandarin. The emoji for sheep was also used to represent positive cases on social media to evade censorship from Chinese social media platforms that were deleting posts related to tensions at iPhone city.

With a growing number of people forced into isolation, rumours and misinformation started to spread.